How to Apply Efex Flexible Mouldings to Furniture (To Be Painted Over)

How to apply Efex Flexible Moldings to Furniture, title says it all!

In the last couple of months you might know that we started to carry Efex Flexible Mouldings, which are downright ahh-mazing. They’re flexible, lightweight silicone mouldings that can be applied to furniture, decor, walls and architectural accents, and much more I’m sure. There aren’t many tutorials that we could find out there, so here we are, with great tips composed with a complete transformation of a furniture piece alongside!

We started off with a quite traditional, rather boring piece:

Our idea was to play off the existing design and go in a more neoclassical direction. Now, here are the steps we took to apply Efex:

1. We cleaned our piece, then selected our Efex designs and measured the spaces on the furniture to plot out the layout.

2. We traced the silhouettes of the Efex shapes to make sure they could stay aligned during the glueing part of the process. Tracing is very important if you want your Efex shapes to look even and aligned!

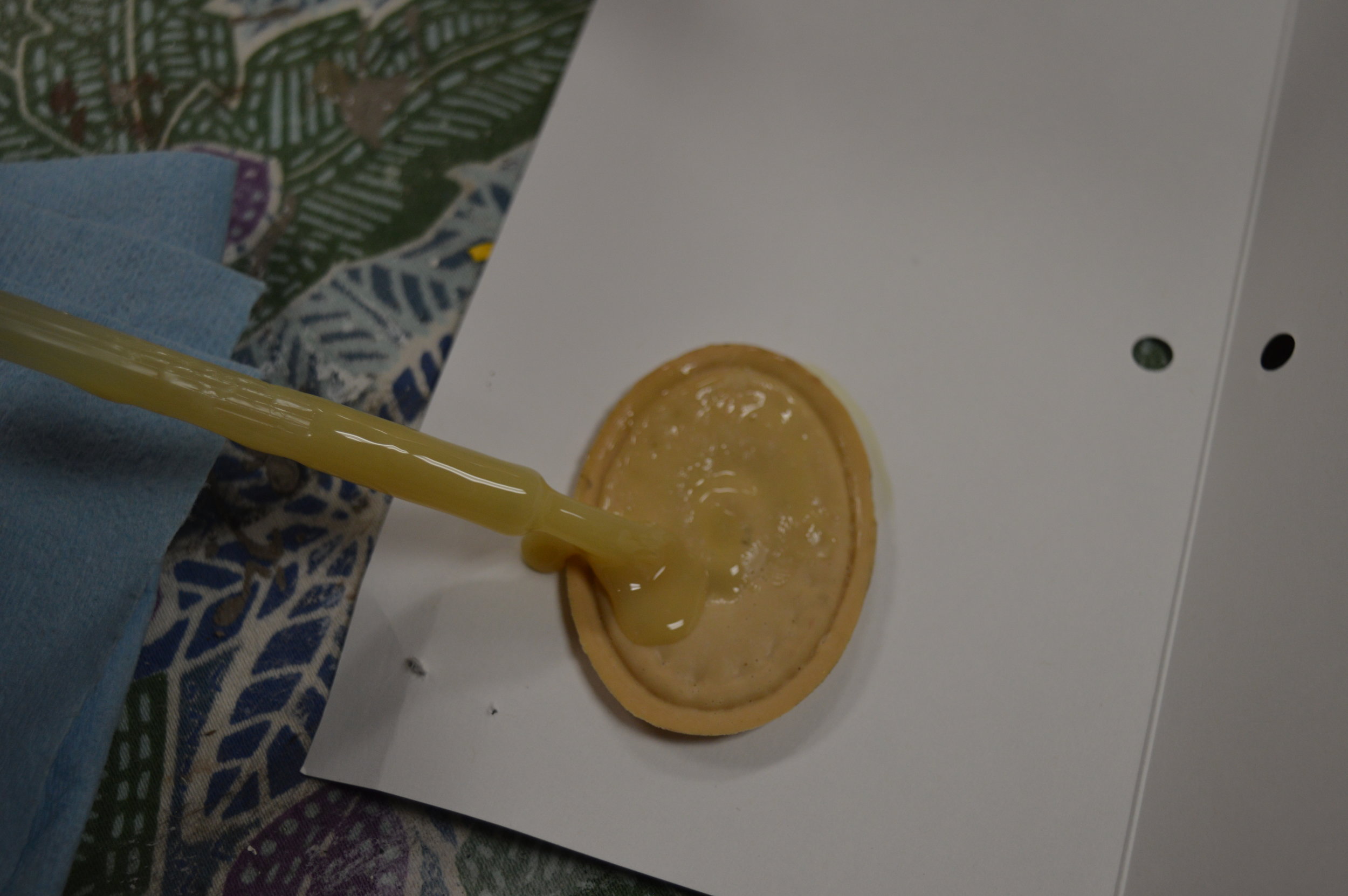

3. We applied contact cement to BOTH the backs of each shape, as well as within the traced shape on the surface of the furniture. These Efex shapes cannot merely be glued on with regular Elmer’s or wood glue— they work together with the contact cement. Basically, the cement dries for 15 minutes on each side, and then when you place the shape down, both cemented sides bond to one another. That way they are on there firmly and won’t budge!

We recommend cementing outside the lines of the traced shape as well, just a little bit, because when you press the silicone Efex down they may flatten and widen out a tiny bit. This ensures that you don’t end up with gaps and loose edges. Make sure you don’t skip areas on the backs of the actual mouldings either. We carry the DAP Weldwood at our Shop & Studio alongside Efex, and we love the small bottles because they have a brush attached to the inside of the cap (like a nail polish bottle) to make life easier.

4. We pressed down each shape, aligning it as best as possible to the traced area and contact cement. A great suggestion is to press just the middle of the shape down first and work outward, because once the cement sides are bonded to one another then it’s very difficult to lift the shape back up. Starting from the middle allows you some wiggle-room (pun intended!) to shift the shape a bit if needed where it hasn’t yet bonded. That being said, it really was not difficult at all to make sure they got on there correctly. Our students and customers agree so far on that as well!

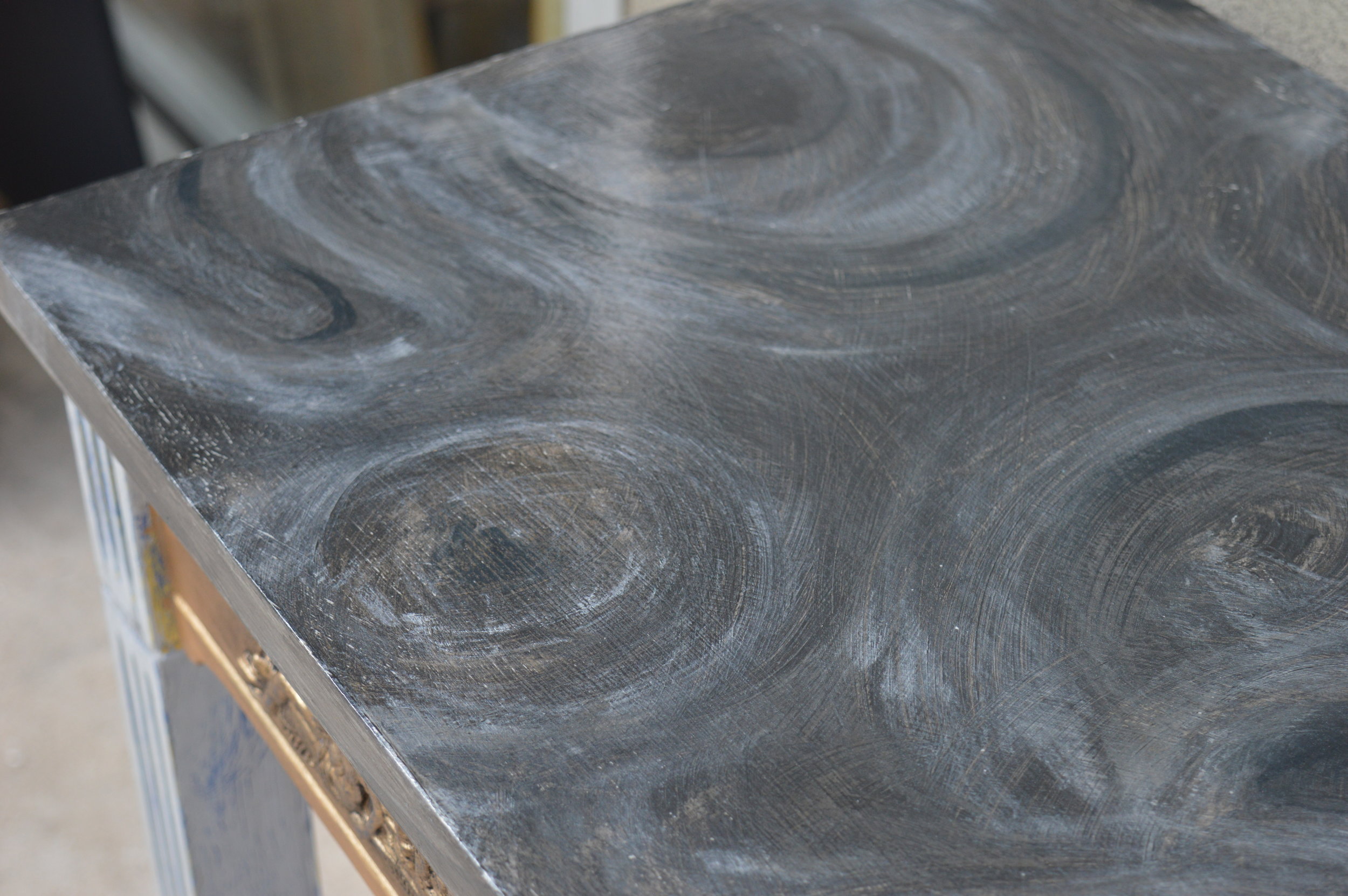

5. We went about finishing our painting technique up right over top! We used layers of Chalk Paint® global Paris Grey, Graphite, Tilton, and Napoleonic Blue. We also used some Modern Masters® Pale Gold on certain areas. We also did a specialty faux stone effect on the top— now THAT DIY tutorial will be for another day!

6. We added Chalk Paint® Black Wax around the Efex mouldings to enhance their appearance.

Check out our finished project! We couldn’t be happier with the quality and look of the Efex mouldings that we chose. We also replaced the knob with a stone one, to go with the faux stone effect in the top.